How Much Are 3PL Cost Germany to Australia?

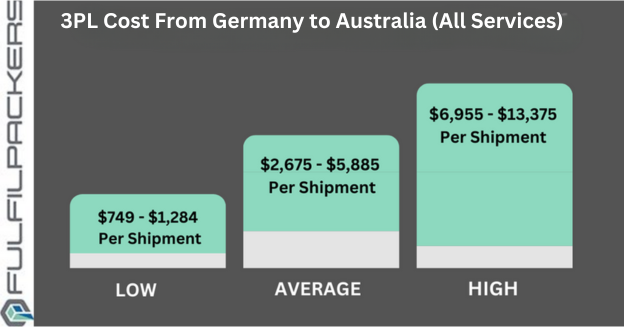

Here is an estimation of the 3PL cost for cross-border logistics from the Germany to Australia, covering shipping, customs clearance, warehousing, and handling:

Discover the key factors shaping 3PL costs from Germany to Australia in 2025 and unlock strategies to optimize your logistics budget!

3PL Services Cost Germany to Australia

Introduction

Managing logistics between Germany and Australia can be a complex task, especially when it comes to understanding 3PL costs.

As businesses continue to expand their global reach, the need for efficient, cost-effective third-party logistics (3PL) solutions has never been greater. This blog explores the key factors influencing these costs and provides insights to help businesses optimize their logistics strategies.

Key Factors Influencing 3PL Costs

Mode of Transportation

Transportation plays a significant role in determining costs. While air freight offers speed, it is costlier compared to sea freight, which is ideal for bulk shipments. Businesses need to strike a balance between speed and cost depending on their needs.Shipment Size and Weight

Larger and heavier shipments incur higher costs as rates are calculated per kilogram or cubic meter. Optimizing packaging and consolidating shipments can help manage these expenses.Customs and Regulatory Fees

Import duties, taxes, and regulatory compliance fees can significantly impact the total logistics costs. Understanding these fees is crucial for accurate budgeting.Warehousing and Storage Costs

Storing goods in a foreign country, such as warehousing in Australia, can add to overall costs. Choosing a cost-effective warehouse with strategic proximity to distribution points can help reduce expenses.

Comparing 3PL Providers

Key Features to Look for in a 3PL Provider

Look for providers that offer transparency in pricing, real-time tracking, and a strong network in both Germany and Australia. A provider’s experience in handling shipping Germany to Australia and vice versa is critical.Benefits of Partnering with Established Providers

Established 3PL providers bring reliability and expertise, ensuring smooth customs clearance, efficient distribution, and reduced risks of delays.

Tips to Optimize 3PL Costs

Consolidating Shipments

Combining smaller shipments into one larger shipment can significantly reduce freight and handling costs.Leveraging Technology for Inventory Management

Using advanced inventory management systems can help reduce overstocking and storage costs, improving overall efficiency.Partnering with Cost-Effective Providers

Select a provider with expertise in handling order fulfillment charges Germany to Australia to minimize unnecessary expenses and delays.

Challenges in Managing 3PL Costs

Fluctuating Freight Rates

Freight rates are highly dynamic and influenced by market demand, fuel prices, geopolitical tensions, and seasonal factors, making accurate budgeting a challenge. Businesses must stay informed about market trends and establish flexible contracts to adapt to these changes.Hidden Fees and Surcharges

Hidden charges like fuel surcharges, peak season fees, and handling costs can significantly inflate overall logistics expenses if not accounted for. Regularly reviewing contracts, auditing invoices, and ensuring transparency in provider agreements are essential steps to avoid unexpected expenses.Delays Due to Regulatory Compliance

Navigating regulatory requirements and customs procedures across different countries can lead to delays and additional costs. Unforeseen changes in trade policies or customs rules can further complicate logistics. Partnering with an experienced 3PL provider with expertise in international regulations helps mitigate these risks and ensures smoother operations.Limited Visibility and Tracking

Inadequate real-time tracking of shipments can lead to inefficiencies, delayed deliveries, and increased costs. Investing in 3PL providers offering advanced tracking systems can help businesses maintain better control over their supply chain.Capacity Constraints and Labor Shortages

Global supply chain disruptions, such as port congestion or labor shortages, can create capacity constraints, driving up logistics costs. Businesses should plan shipments well in advance and explore alternative routes or providers to manage such challenges.

Future Trends in 3PL Costs

Technology-Driven Cost Reductions

Emerging technologies like automation, artificial intelligence, and blockchain are set to transform logistics operations. These innovations improve route optimization, enhance inventory management, and reduce administrative overhead, significantly lowering costs.Sustainability and Its Impact on Pricing

The push for eco-friendly shipping practices, such as using electric or hybrid delivery vehicles, may initially increase costs. However, long-term cost savings through fuel efficiency, regulatory incentives, and improved brand reputation make sustainable practices an attractive investment.Expansion of Digital Freight Platforms

Digital freight platforms are gaining traction, offering real-time pricing, increased transparency, and streamlined operations. These platforms enable businesses to compare rates and select cost-effective providers quickly.Focus on Supply Chain Resilience

As businesses prioritize resilience in their supply chains, they are likely to invest in diversified logistics networks and local warehousing, which may initially increase costs but provide long-term stability against disruptions.Data-Driven Decision Making

Big data analytics will play a crucial role in identifying cost-saving opportunities, predicting demand fluctuations, and optimizing logistics processes. Businesses leveraging data insights can stay ahead of competitors and reduce unnecessary expenses.

Pallet Type Comparison: Weight, Load, and Use Cases

3PL (Third-Party Logistics) Costs (Various cities)

Conclusion

Cross-border logistics between Germany and Australia require a strategic approach to manage costs effectively. By leveraging technology, partnering with reliable 3PL providers, and focusing on cost optimization, businesses can navigate the complexities of global supply chains. Whether managing shipping Australia to Germany or streamlining order fulfillment charges Germany to Australia, a well-planned logistics strategy ensures cost-effectiveness and operational success.

FAQs on 3PL Costs Between Germany and Australia

What Is the Average Shipping Cost for 3PL?

Average costs depend on factors like shipment size, mode of transport, and customs fees, with air freight being more expensive than sea freight.How Can Businesses Save on 3PL Costs?

Consolidating shipments, optimizing inventory, and partnering with experienced providers are effective ways to reduce costs.Are 3PL Costs Higher for Small Businesses?

Small businesses may face higher per-unit costs due to smaller shipment volumes, but negotiating contracts can help.What Role Does Technology Play in Reducing Costs?

Technology helps in real-time tracking, inventory optimization, and cost forecasting, making logistics more efficient.Are There Hidden Costs in 3PL Services?

Yes, costs like fuel surcharges and warehousing fees can add up. Reviewing contracts thoroughly is essential.