What Are the 3PL Costs New Zealand to Australia?

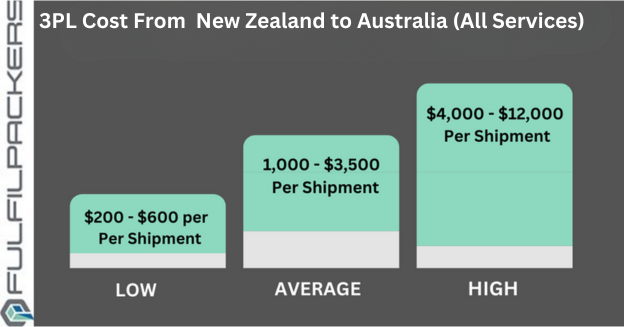

Here is an estimation of the 3PL cost for cross-border logistics from the New Zealand to Australia, covering shipping, customs clearance, warehousing, and handling:

Unlocking the True Costs of 3PL Services Between New Zealand and Australia in 2025.

3PL Services Cost New Zealand to Australia

Introduction

When managing international supply chains, businesses need to understand the associated costs of third-party logistics (3PL) services. With global trade between countries like New Zealand and Australia on the rise, it's essential to assess how 3PL costs affect overall business expenses.This blog explores the various factors impacting 3PL costs for shipping goods from New Zealand to Australia in 2025, offering valuable insights for businesses looking to optimize their logistics operations.

Key Factors Influencing 3PL Costs

Understanding the factors that impact 3PL costscan help businesses plan and budget effectively. The main components of cost are:

Mode of Transportation: Air Freight vs. Sea Freight

The choice between air and sea freight plays a pivotal role in determining the cost of 3PL services. Air freight is faster but more expensive, making it ideal for time-sensitive shipments.

On the other hand, sea freight offers a more affordable solution for larger and bulkier shipments, though it takes longer to reach its destination.

Shipment Size and Weight

The size and weight of the shipment directly influence 3PL costs. Heavier and larger shipments require more space and energy to transport, increasing the overall cost. Rates are typically calculated based on the weight or volume of the goods being shipped.

Customs and Regulatory Compliance

Shipping internationally involves navigating customs regulations and paying necessary duties. The reverse logistics cost New Zealand to Australia can also include additional charges for compliance with these regulations, which vary from country to country.

Average 3PL Costs for Shipping from New Zealand to Australia

Shipping Costs Breakdown

The average 3PL cost for shipping from New Zealand to Australia typically depends on various elements such as the mode of transport, shipment size, and delivery speed.

For example, sea freight can cost around $1,000 to $2,000 for a standard 20-foot container, while air freight can be significantly more expensive, with costs ranging between $4,000 and $8,000 depending on the weight and urgency.

Estimated 3PL Cost Ranges in 2025

In 2025, businesses can expect a slight increase in 3PL costs due to inflation and fluctuations in fuel prices. However, with proper planning, companies can mitigate these cost increases by optimizing their logistics and working with experienced providers.

How 3PL Logistics Companies in New Zealand Manage Costs

Partnering with Reliable 3PL Providers

Selecting the right third-party logistics provider is critical to managing costs effectively. A reputable provider can help optimize routes, consolidate shipments, and offer competitive pricing. By partnering with the right provider, businesses can gain access to cost-effective solutions that streamline operations and reduce expenses.

Optimizing Shipment Volume and Frequency

One way logistics companies manage 3PL costs is by consolidating shipments. Combining smaller shipments into one larger shipment reduces the overall cost per unit, offering savings in both transportation and handling.

Additional Costs to Consider

While freight is a major component of 3PL expenses, other factors also contribute to overall costs.

Warehousing Costs in Australia

When goods arrive in Australia, businesses must account for warehousing costs. Storing inventory cost New Zealand may vary depending on the type of goods and the duration of storage required. Generally, the cost of warehousing can range from $10 to $50 per pallet per month in Australia.

Order Fulfillment Charges New Zealand to Australia

Order fulfillment is another cost to factor in. This includes the picking, packing, and shipping of goods. Order fulfillment charges New Zealand to Australia can add up quickly, particularly for businesses that ship frequently or in small batches.

Taxes and Customs Fees

International shipping involves additional charges, such as taxes and customs duties, which can significantly increase 3PL costs. These fees depend on the type of goods being shipped and the customs regulations of both New Zealand and Australia.

Tips to Reduce 3PL Costs

Managing 3PL costs requires careful planning and strategic decision-making. Here are some tips to help businesses reduce costs:

Consolidating Shipments

Combining smaller shipments into one larger shipment can help reduce transportation costs. This strategy works well for businesses that frequently ship smaller loads but want to save on shipping rates.

Leveraging Technology and Automation

Using technology such as real-time tracking systems, inventory management software, and automated fulfillment processes can reduce errors and delays, minimizing the potential for hidden costs.

Negotiating Contracts with 3PL Providers

Negotiating long-term contracts with your third-party logistics provider can lead to better pricing and more favorable terms. Providers are often willing to offer discounts for businesses that commit to larger volumes or longer contracts.

Challenges in Managing 3PL Costs

While there are many ways to manage and optimize 3PL costs, businesses must also deal with certain challenges:

Fluctuating Freight Rates

Freight rates fluctuate due to factors like fuel prices, seasonal demand, and global events. Businesses need to monitor these fluctuations and adjust their strategies accordingly.

Hidden Fees and Surcharges

Always review contracts to avoid hidden charges, such as fuel surcharges or peak season fees. These charges can add up quickly and significantly affect overall logistics costs.

Delays Due to Regulatory Compliance

Regulatory changes and customs delays can result in unforeseen costs. Working with experienced logistics providers helps minimize these risks and ensures smooth delivery.

Future Trends in 3PL Costs

Technology-Driven Cost Reductions

The use of automation, AI, and block chain technology is expected to play a significant role in reducing 3PL costs in the future. These technologies enable businesses to streamline operations, cut down on human error, and improve overall efficiency.

Sustainability and Its Impact on Pricing

Eco-friendly shipping practices may become more cost-effective as regulatory incentives and consumer demand for sustainable practices grow. As sustainability becomes a higher priority, businesses should consider it as a factor in cost management.

Pallet Type Comparison: Weight, Load, and Use Cases

3PL (Third-Party Logistics) Costs (Various cities)

Conclusion

The 3PL cost from New Zealand to Australia in 2025 will be influenced by various factors, including transportation mode, shipment size, and regulatory requirements.Businesses can manage these costs by partnering with reliable providers, optimizing shipment volume, and leveraging technology to streamline operations. By staying informed about industry trends and continuously optimizing logistics processes, businesses can successfully reduce costs while maintaining efficient operations.

FAQs

1. What is the average 3PL cost from New Zealand to Australia in 2025?

The average 3PL cost depends on shipment size, transport mode, and delivery speed, ranging from $1,000 to $8,000.

2. How can I reduce order fulfillment charges New Zealand to Australia?

Consolidating shipments, optimizing packaging, and leveraging technology can help reduce fulfillment charges.

3. What are reverse logistics costs New Zealand to Australia?

Reverse logistics costs involve return shipping fees, handling charges, and potential customs duties.

4. How can warehousing in Australia affect 3PL costs?

Warehousing costs depend on inventory size, storage duration, and warehouse location. Strategic planning helps manage these costs.

5. How do storing inventory cost New Zealand and shipping affect overall 3PL expenses?

Storing inventory and shipping costs together influence overall 3PL expenses. Optimizing inventory and shipping methods can reduce costs.