The Ultimate Guide to E-commerce Fulfillment: From Order to Delivery

Understanding E-commerce Order Fulfillment

E-commerce order fulfillment is the backbone of any successful online retail operation. In simple terms, it involves everything that happens from the moment a customer places an order until that order reaches their doorstep. This process includes receiving inventory, storing it, picking and packing items, and finally shipping them to customers. Streamlined fulfillment is essential not only to meet growing customer expectations but to stay competitive in a market dominated by giants.

Key points about e-commerce order fulfillment:

On-time Delivery: 72% of shoppers prioritize on-time delivery over other reasons to shop with a retailer.

Customer Loyalty: 38% of shoppers won’t return if they have a poor delivery experience.

Speed Matters: 88% of consumers are willing to pay for faster delivery.

Growing e-commerce businesses often struggle to meet these high demands. That’s where third-party logistics (3PL) providers like FulfilPackers come into play. These companies specialize in managing the entire order fulfillment process, allowing you to focus on what you do best—growing your business.

FulfilPackers offers custom solutions for e-commerce retailers, handling everything from inventory management to fast and reliable shipping. Their advanced technology and strategic fulfillment centers ensure that your products reach customers quickly and in perfect condition.

In this guide, we'll dive deeper into the order fulfillment process, explore different strategies, and show you how to optimize your operations for maximum efficiency and customer satisfaction.

What is E-commerce Order Fulfillment?

Key Components of Order Fulfillment

E-commerce order fulfillment is the entire process from the moment a customer places an order to when the package arrives at their doorstep. It’s a critical part of any online business, involving multiple steps to ensure customer satisfaction.

Definition and Process Steps

Order fulfillment includes several key steps:

Receiving Inventory: This involves getting products from suppliers and stocking them in a warehouse.

Storage: Properly organizing and storing products so they can be easily accessed.

Picking: Selecting the right items from storage to fulfill an order.

Packing: Safely packaging items to ensure they arrive in perfect condition.

Shipping: Sending the packaged items to customers using various carriers.

Returns: Handling any returns or exchanges from customers.

Each of these steps requires careful coordination and often sophisticated technology to execute efficiently.

In-house vs. 3PL

Businesses can manage fulfillment in-house or outsource to a third-party logistics (3PL) provider like FulfilPackers.

In-house Fulfillment:

Pros: Complete control over the process, potentially lower costs for small volumes.

Cons: Time-consuming, requires significant resources, and can become costly as order volumes grow.

3PL Fulfillment:

Pros: Expertise, scalable solutions, and often cost-effective for larger volumes.

Cons: Less control over the process and potential for hidden fees.

B2B vs. B2C

Order fulfillment can vary significantly between Business-to-Business (B2B) and Business-to-Consumer (B2C) models.

B2B Fulfillment: Often involves larger orders, bulk shipments, and may require compliance with EDI regulations.

B2C Fulfillment: Typically involves smaller, individual orders with a focus on speed and accuracy.

Receiving

Receiving inventory is the first step in the fulfillment process. It involves:

Advance Shipping Notice: Knowing when and what is arriving.

Inspection: Checking for damages or discrepancies.

SKU Assignment: Labeling products for easy tracking.

Inventory Management Software: Using technology to keep track of stock levels.

Storage

Proper storage is crucial for efficient order fulfillment. Key aspects include:

Organization: Arranging products logically to speed up picking.

Security: Ensuring products are safe from theft or damage.

High-demand Items: Placing popular items in easily accessible locations.

Picking and Packing

The picking and packing process is where efficiency really counts.

Pick Lists: Guides for workers to know what items to pick.

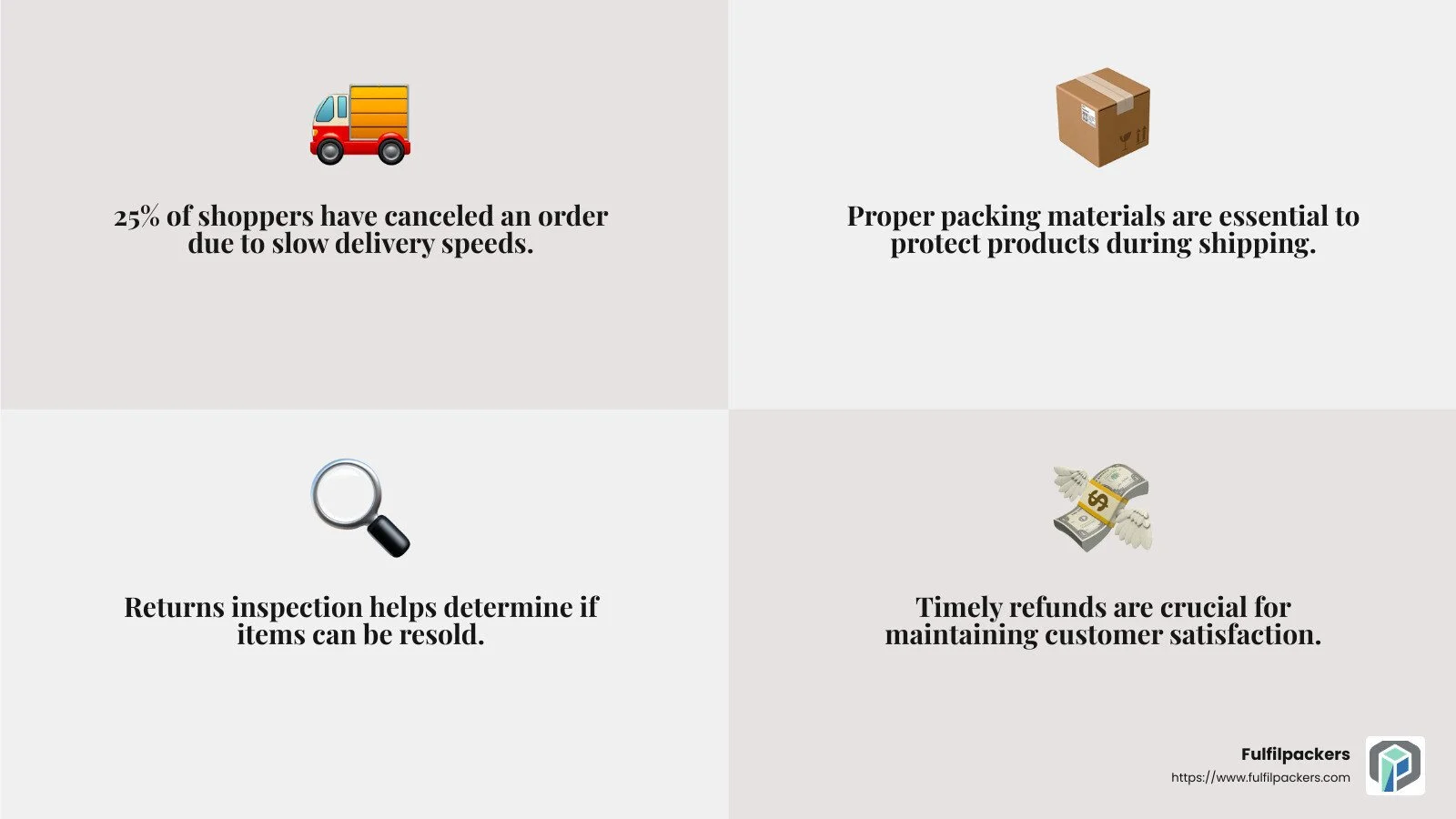

Packing Materials: Using appropriate materials to protect products.

Packing Slips: Including a list of items in the package.

Custom Packaging: Enhancing the unboxing experience for customers.

Shipping

Shipping is the final step before an order reaches the customer.

Carrier Selection: Choosing the best carrier based on cost and delivery time.

Shipping Labels: Generating accurate labels to avoid delays.

Tracking: Providing customers with tracking information.

Delivery Times: Meeting or exceeding delivery expectations.

Returns Management

Handling returns efficiently is crucial for maintaining customer satisfaction.

Returns Policy: Clear instructions for customers on how to return items.

Inspection: Checking returned items for resale or disposal.

Restocking: Adding returned items back to inventory if they are in good condition.

Refunds: Issuing timely refunds to customers.

By mastering these components, you can ensure a smooth and efficient e-commerce order fulfillment process that meets customer expectations and drives repeat business. Next, we’ll explore different fulfillment strategies to help you decide which is best for your business.

The E-commerce Order Fulfillment Process

Receiving Inventory

Receiving inventory is the first step in the e-commerce order fulfillment process. It ensures that products are ready to be picked, packed, and shipped to customers. Here are the key steps involved:

Advance Shipping Notice (ASN): This is a heads-up sent to the fulfillment center, detailing what products are arriving and when. It helps the warehouse prepare for incoming shipments.

Inspection: Upon arrival, staff inspect the goods for any damage or discrepancies. This step is crucial to catch issues early and avoid stocking damaged items.

SKU Assignment: Each product gets a Stock Keeping Unit (SKU) for easy tracking. If it’s a new product, it gets a new SKU.

Inventory Management Software (IMS): The IMS logs the products into the system, updating stock levels in real-time.

Storage

Once the inventory is received and logged, it needs to be stored efficiently. Proper storage is vital for fast and accurate order fulfillment.

Organization: Products are arranged logically, often with high-demand items placed in easily accessible locations.

Security: Measures are taken to ensure products are safe from theft or damage.

Inventory Management: The IMS helps keep track of stock levels, ensuring that older stock is sold first to prevent obsolescence.

Picking and Packing

The picking and packing stage is where efficiency can make or break your fulfillment process.

Pick Lists: These are generated by the IMS and guide workers on what items to pick and from where.

Packing Materials: Appropriate materials are chosen to protect products during shipping. This could include bubble wrap, air fillers, or custom packaging.

Packing Slips: These are added to the package and list the items included, aiding both the packer and the customer.

Custom Packaging: Some businesses opt for branded or custom packaging to improve the customer experience.

Shipping

Shipping is the final step before the customer receives their order. It involves several critical components:

Carrier Selection: Choosing the best carrier based on cost, delivery speed, and reliability.

Shipping Labels: Accurate labels are generated to ensure the package reaches the correct destination without delays.

Tracking: Providing customers with tracking information helps them know when to expect their package.

Delivery Times: Meeting or exceeding delivery expectations is key to customer satisfaction.

Returns Management

Handling returns efficiently is crucial for maintaining customer satisfaction and operational efficiency.

Returns Policy: Clear instructions should be provided to customers on how to return items.

Inspection: Returned items are checked for resale or disposal.

Restocking: If the returned items are in good condition, they are added back to inventory.

Refunds: Timely refunds are issued to keep customers happy and encourage repeat business.

By mastering these components, you can ensure a smooth and efficient e-commerce order fulfillment process that meets customer expectations and drives repeat business.

Next, we’ll explore different fulfillment strategies to help you decide which is best for your business.

E-commerce Fulfillment Strategies

Choosing the right e-commerce fulfillment strategy can make or break your business. Let's explore three of the most popular strategies: in-house fulfillment, third-party logistics (3PL), and dropshipping.

In-house Fulfillment

In-house fulfillment means you handle everything yourself—from storing inventory to packing and shipping orders.

Pros:

Control: You have complete control over the entire process. You can ensure everything meets your standards.

Lower Upfront Costs: Initially, you can store items at home or in a small space, saving on warehousing costs.

Accessibility: Anyone can start from their home, making this option very accessible.

Cons:

Time-consuming: Packing and shipping orders yourself can take up a lot of your time.

Long-term Costs: As your business grows, you’ll need more space and staff, which can become costly.

In-house fulfillment is ideal for startups or very large companies that want full oversight.

Third-party Logistics (3PL)

Third-party logistics (3PL) involves outsourcing your fulfillment process to a specialized provider like FulfilPackers.

Pros:

Outsourcing: You can focus on other areas of your business like marketing and product development.

Cost Savings: 3PL providers often have bulk shipping rates and other cost-saving measures.

Expertise: You benefit from the expertise of logistics professionals who can optimize your operations.

Cons:

Less Control: You may have less control over the fulfillment process.

Initial Costs: There can be setup fees and ongoing costs associated with 3PL services.

FulfilPackers offers comprehensive 3PL services, handling everything from receiving inventory to shipping and returns, allowing you to scale your business efficiently.

Dropshipping

Dropshipping lets you sell products without ever handling inventory.

Pros:

Low Investment: You don’t need to buy inventory upfront.

Reduced Risk: Since you only purchase items when you make a sale, there’s less financial risk.

No Warehousing: You don’t need to worry about storage or shipping logistics.

Cons:

Reduced Control: You rely on suppliers to fulfill orders, which can affect quality and delivery times.

Longer Delivery Times: Shipping can take longer since products are sent directly from the manufacturer to the customer.

Lower Margins: You often make less profit per sale because suppliers charge more for dropshipping services.

Dropshipping is great for new businesses looking to minimize initial investment and risk.

Choosing the right fulfillment strategy depends on your business size, budget, and goals. Next, we'll discuss how to optimize your fulfillment operations for maximum efficiency and customer satisfaction.

Optimizing Your E-commerce Fulfillment

Location Strategy

Where you fulfill orders from is crucial in meeting customer expectations for delivery cost and speed. Urban fulfillment centers are becoming popular because they allow quick and affordable shipping to densely populated areas. By placing your inventory close to your customers, you can reduce shipping zones—the distance packages travel—which generally lowers shipping costs and transit times.

Distributing inventory across multiple locations also helps. This way, you can leverage ground shipping, which is cheaper than air shipping and often faster than shipping from a distant location.

Technology Integration

Seamless technology integration is key to efficient e-commerce order fulfillment. Software that syncs with your ecommerce platforms and online marketplaces can manage orders across sales channels without manual uploads or duplicate data entry.

For example, once an order is placed, your warehouse management system (WMS) can automatically alert staff to pick, pack, and ship the items. Real-time data from these systems can update stock levels, send tracking information to customers, and provide insights for better decision-making.

Inventory Visibility

Knowing what you have in stock and where it’s located is essential. Real-time visibility into inventory quantities across all fulfillment locations helps you proactively order more inventory to prevent stockouts. This is crucial for maintaining customer satisfaction, especially when you promise fast shipping.

Using inventory management software, you can track stock levels, set reorder points, and get alerts when inventory is low. This helps you maintain optimal stock levels and avoid the pitfalls of overselling or running out of popular items.

Enhancing Customer Experience

Customer experience is paramount in e-commerce. Fast shipping is a major expectation, with many customers now expecting 2-day or even same-day delivery. To meet these expectations, keep transit times down and costs low by optimizing your fulfillment locations and leveraging technology integrations.

Branded packaging can also improve the customer experience. Adding personal touches like thank you notes, coupons, or free gifts can leave a lasting impression and encourage repeat business.

Communication is another critical aspect. Ensure that customers receive timely updates on their order status, including tracking information. Clear and consistent communication helps manage customer expectations and reduces the likelihood of negative reviews.

By implementing these strategies, you can optimize your e-commerce order fulfillment process, ensuring higher customer satisfaction and better operational efficiency. Next, we’ll answer some frequently asked questions about e-commerce order fulfillment.

Frequently Asked Questions about E-commerce Order Fulfillment

What is the best fulfillment solution?

The best fulfillment solution depends on your business size, product type, and order volume. Here are three main options to consider:

In-house Fulfillment: Ideal for small businesses or those with unique shipping needs. You control the entire process but must handle all logistics, which can be time-consuming and costly as you scale.

Third-party Logistics (3PL): Great for growing businesses. Outsourcing to a 3PL like Fulfilpackers can save costs and leverage their expertise in storage, packing, and shipping. They also offer advanced inventory management and can handle peak seasons and volume spikes efficiently.

Dropshipping: Perfect for startups with limited capital. You don't hold inventory; instead, suppliers ship directly to customers. However, this can lead to longer delivery times and less control over the customer experience.

How do I fulfill an online order?

Fulfilling an online order involves several steps:

Receiving Inventory: Ensure your inventory is stocked and organized. Use inventory management software to track stock levels and anticipate reorders.

Warehousing and Storage: Store your products in a way that makes them easy to pick and pack. This includes organizing high-demand items for quick access.

Picking and Packing: Generate pick lists for your staff. Use appropriate packing materials to protect products during shipping and include packing slips.

Shipping: Select a carrier, print shipping labels, and send tracking information to customers. Aim for fast and reliable delivery to meet customer expectations.

Returns Management: Have a clear returns policy. Inspect returned items, restock them if appropriate, and process refunds promptly.

How much does e-commerce fulfillment cost?

Fulfillment costs vary based on several factors:

Product Size and Weight: Heavier and larger items cost more to store and ship.

Order Volume: Higher volumes can reduce per-unit costs due to economies of scale.

Storage Fees: Monthly fees are based on the volume of space your inventory occupies.

Shipping Costs: These depend on the carrier, delivery speed, and distance. Using ground shipping and optimizing fulfillment locations can lower costs.

Returns and Customer Service: Handling returns and providing customer support can add to your expenses.

Request a detailed quote today from Fulfilpackers and discover how we can meet your needs with precision and clarity!

Conclusion

E-commerce order fulfillment is a vital part of any online business. From receiving inventory to managing returns, each step in the process impacts customer satisfaction and your bottom line.

Summary: We've explored the ins and outs of e-commerce fulfillment, including in-house and third-party logistics (3PL) options, and even dropshipping. Each has its own benefits and challenges, but the right choice depends on your business size, product type, and order volume.

Importance of Strategy: A well-thought-out fulfillment strategy can be a game-changer. Efficient fulfillment not only meets but exceeds customer expectations, leading to higher satisfaction and repeat business. It also helps in managing costs and scaling operations effectively.

FulfilPackers: As a trusted 3PL provider, we specialize in streamlining your fulfillment process. From warehousing to shipping, we handle it all so you can focus on growing your business. Our advanced technology and strategic locations ensure fast, reliable, and cost-effective delivery.

Future Trends: The future of fulfillment is exciting and full of innovations. Technologies like blockchain for transparency, drone delivery for speed, and AI for smarter operations are set to revolutionize the industry. Staying ahead of these trends can give your business a competitive edge.

To optimize your fulfillment strategy and ensure customer satisfaction, consider partnering with a reliable 3PL provider. Explore our services to see how we can help you scale efficiently and meet your customers' expectations.