Boost Your Supply Chain Efficiency: Proven Strategies and Tips

Importance of Efficient Supply Chain Management

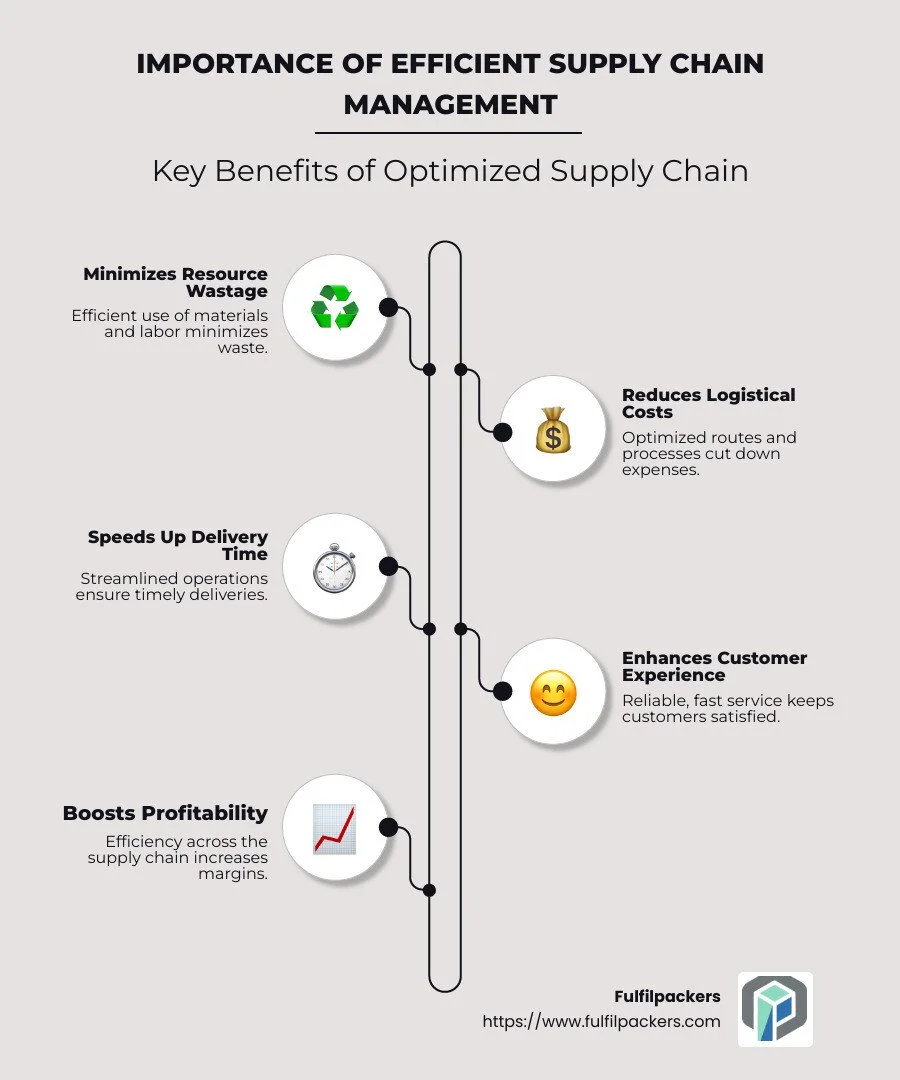

Efficient supply chain management is crucial for any business looking to reduce costs, minimize waste, and maximize profits. It ensures that resources are used effectively, products are delivered on time, and customer satisfaction is achieved. Here are some quick takeaways for anyone needing a swift overview:

Minimizes resource wastage

Reduces logistical costs

Speeds up delivery time

Improves customer experience

Now, let's dive deeper to understand why this matters.

Efficient supply chain management goes beyond just meeting customer demands. It encompasses every stage of the production process—from procurement of raw materials to the distribution of finished products. Effective supply chain management keeps your business ahead by balancing cost-efficiency and quality while remaining responsive to market needs.

By focusing on key performance metrics like cost and quality, businesses can pinpoint their strengths and weaknesses, making room for continuous improvement.

At Fulfilpackers, we've honed our expertise in efficient supply chain management by leveraging cutting-edge technology and robust systems. Our global reach and 3PL solutions cater specifically to e-commerce enterprises, ensuring that your business can scale seamlessly while maintaining high-efficiency levels.

What is Efficient Supply Chain Management?

Efficient supply chain management is all about optimizing every step of the supply chain to use fewer resources while achieving more. It's not just about moving products from point A to point B. It's about doing so in a way that minimizes costs, reduces waste, and maximizes profits.

Goals of Efficient Supply Chain Management

The primary goals are:

Cost Minimization: Keeping costs low at every stage, from procurement to distribution.

Resource Optimization: Using resources like time, labor, and materials as efficiently as possible.

Profitability: Ensuring that all these efficiencies translate into higher profits for the business.

Cost Minimization

One of the biggest advantages of an efficient supply chain is cost minimization. This means cutting excess costs related to order processing, inventory management, and logistics.

Resource Optimization

Resource optimization is about making the best use of available resources. This includes everything from raw materials to human labor.

Profitability

An efficient supply chain directly impacts profitability. When costs are minimized and resources are optimized, the bottom line improves.

Key Takeaways

Efficient supply chain management minimizes costs, optimizes resources, and improves profitability.

By focusing on these goals, businesses can not only meet customer demands but also stay ahead of the competition. Next, we'll explore the key elements that make up an efficient supply chain.

Key Elements of Efficient Supply Chain Management

Efficient supply chain management involves several crucial components. Let's explore the key elements that can help your business achieve a more streamlined and effective supply chain.

Strong Supplier Relationships

Building strong relationships with your suppliers is essential for a smooth and efficient supply chain. Good communication and reliability from suppliers can help you avoid delays and ensure consistent quality.

Example: A reliable supplier can track the inventory-in-process phase, ensuring that raw materials are processed into finished products efficiently. This impacts the quality of your products and helps you avoid shortages or delays.

Demand Forecasting

Accurate demand forecasting is the backbone of efficient supply chain management. By predicting future customer needs, businesses can align their production schedules and inventory levels with actual market demands.

Inventory Management

Effective inventory management ensures that you have the right amount of stock at the right time. Real-time tracking systems can help monitor inventory levels, minimizing overstocking and stockouts.

Fact: Modern inventory management software (IMS) provides real-time inventory tracking, helping businesses avoid stockouts, pending orders, and excessive storage costs.

Quality Assurance

Maintaining high quality at every stage of the supply chain is critical. Quality-related metrics help identify any problems that may arise, ensuring that only top-quality products reach your customers.

Coordination

Coordination between different stages of the supply chain is vital for efficiency. This includes synchronizing procurement, production, and distribution processes to optimize the flow of goods.

Quote: "Effective coordination can lower a company's overall costs and boost its profitability." — Investopedia

Multiple Manufacturers

Using multiple manufacturers can add flexibility to your supply chain. This diversification helps mitigate risks associated with relying on a single supplier or manufacturer.

By focusing on these key elements, businesses can improve their supply chain efficiency, reduce costs, and improve customer satisfaction.

Next, we'll explore how to measure supply chain efficiency using specific metrics.

How to Measure Supply Chain Efficiency

Measuring supply chain efficiency is essential for identifying strengths and weaknesses in your operations. By tracking specific metrics, you can make informed decisions to optimize your supply chain. Let's break down the key metrics you should focus on.

Metrics

To gauge supply chain efficiency, you need to measure the right metrics. These metrics fall into three main categories: cost, quality, and time.

Cost

Cost-efficiency metrics help you understand how much it costs to move goods from one stage of the supply chain to another. This includes:

Order Processing Costs: The expenses involved in processing orders.

Inventory Management Costs: The costs associated with storing and managing inventory.

Fact: Businesses using advanced Warehouse Management Systems (WMS) often see a 20-30% reduction in operational costs within the first year.

Quality

Quality metrics measure the quality of goods at each stage of the supply chain. This helps identify issues that could impact the final product. Key quality metrics include:

Defect Rates: The percentage of products that fail to meet quality standards.

Return Rates: The percentage of products returned by customers due to defects or dissatisfaction.

Time

Time-related metrics focus on how quickly and efficiently your supply chain operates. Important time metrics include:

Lead Time: The time it takes from placing an order to receiving the goods.

On-Time Delivery Rate: The percentage of orders delivered on or before the promised delivery date.

Quote: "Effective coordination can lower a company's overall costs and boost its profitability." — Investopedia

Performance Indicators

Performance indicators are specific metrics that provide insights into your supply chain's efficiency. Some key performance indicators (KPIs) include:

Inventory Turnover Rate: How often inventory is sold and replaced over a period.

Order Accuracy: The percentage of orders delivered without errors.

Average Cost per Unit for Fulfillment and Shipping: The average expense incurred to fulfill and ship each unit.

Analysis

Analyzing these metrics allows you to identify areas for improvement. Use data analytics tools to:

Track Trends: Monitor changes in key metrics over time to spot trends and patterns.

Benchmark Performance: Compare your metrics against industry standards or competitors.

Identify Bottlenecks: Pinpoint stages in the supply chain where delays or inefficiencies occur.

By focusing on these metrics and performance indicators, you can gain a clear picture of your supply chain's efficiency. This will help you make data-driven decisions to optimize your operations.

Next, we'll explore proven strategies to improve supply chain efficiency.

Proven Strategies to Improve Supply Chain Efficiency

Expand Supply Chain Visibility

Increasing visibility in your supply chain is crucial. Real-time data and inventory management software (IMS) are your best friends here. Modern IMS allows you to track inventory levels as they move through various stages—reception, storage, packaging, picking, and shipping.

Fact: Implementing an IMS can help you avoid stockouts, pending orders, and excessive storage costs. It also offers data analytics for informed business decisions, like inventory forecasting.

Develop Strong Supplier Relationships

Communication with your suppliers is key. A reliable supplier helps you avoid shortages, delays, and quality issues from the start.

Quote: "A good relationship with suppliers allows better planning and helps avoid problems." — Fulfilpackers

Flexibility and quality are essential. Weed out suppliers causing consistent issues. Once you find reliable ones, nurture those relationships through clear and open communication.

Automate Supply Chain Processes

Automation can significantly improve efficiency. By automating tasks like order processing and shipping, you reduce human error, increase speed, and save costs.

Example: Automated warehouses can cut down time, effort, and logistics errors.

Fact: Many e-commerce companies use technologically advanced third-party logistics partners (3PLs) to benefit from automation without high upfront costs.

Implement Supply Chain Software

Using the right software can streamline your operations. Consider a Warehouse Management System (WMS) that connects to your IMS. This helps automate order processing, provides real-time inventory tracking, and offers data analytics.

Fact: Businesses using a WMS often see a 20-30% reduction in operational costs within the first year.

Integration is key. Ensure your WMS integrates well with other systems like Customer Relationship Management (CRM) software.

Cultivate Supply Chain Experts

Your supply chain is only as good as the people managing it. Training your employees is crucial. Develop a training plan that covers the new systems and procedures you've implemented.

Quote: "An operation is only as good as its employees." — Fulfilpackers

Employee feedback is valuable. Open channels for feedback to continuously improve your training process. Cultivating expertise within your team can lift your overall supply chain quality.

By focusing on these strategies, you can significantly improve your supply chain efficiency. Next, we'll explore the differences between efficient and responsive supply chain management.

Efficient Supply Chain Management vs. Responsive Supply Chain Management

When it comes to supply chain management, businesses often grapple with choosing between efficiency and responsiveness. Understanding the differences can help you make the best decision for your organization.

Focus and Goals

Efficient supply chains are all about maximizing productivity while keeping costs low. The main goal is to streamline processes, eliminate waste, and optimize resources to deliver products at competitive prices.

Responsive supply chains, on the other hand, prioritize agility and customer satisfaction. The goal is to quickly adapt to changes in market conditions, customer demands, or unforeseen disruptions, even if it means higher operational costs.

Inventory Levels

In an efficient supply chain, inventory levels are minimized to reduce carrying costs and improve capital efficiency. Techniques like just-in-time inventory are commonly used.

However, a responsive supply chain maintains higher inventory levels to ensure flexibility and mitigate risks such as stockouts or supply disruptions. Strategies like safety stock and buffer inventory are crucial here.

Processes

Efficient supply chains rely on standardized workflows and optimized production schedules. The focus is on eliminating inefficiencies and reducing cycle times.

Conversely, responsive supply chains use agile manufacturing and dynamic resource allocation. These processes allow for quick adjustments to meet changing demands.

Agility

Agility is a hallmark of responsive supply chains. They can quickly adapt to sudden changes in demand or supply conditions. This is achieved through flexible processes and real-time data analytics.

Efficient supply chains are less agile due to their focus on cost minimization and rigid processes. However, they excel in stable environments where demand is predictable.

Lead Times and Costs

Responsive supply chains often have shorter lead times because they prioritize speed and flexibility. This can lead to higher costs in production, transportation, and inventory holding.

Efficient supply chains typically have longer lead times as they focus on bulk production runs to minimize unit costs. This approach reduces costs but can delay delivery times.

Real-World Example

Imagine you're launching a new smartphone. With a responsive supply chain, you could quickly ramp up production to meet high demand. In contrast, an efficient supply chain would focus on bulk production to lower costs, resulting in longer lead times.

Fact: According to a Harvard Business Review study, companies like Wal-Mart and Amazon have successfully integrated both agility and efficiency into their supply chains, achieving a competitive edge.

Quote: "Agility, adaptability, and alignment are the keys to a sustainable competitive advantage." — Harvard Business Review

Balancing efficiency and responsiveness is vital for modern supply chains. By understanding these differences, you can better align your supply chain strategy with your business goals.

Next, we'll dive into some frequently asked questions about efficient supply chain management.

Frequently Asked Questions about Efficient Supply Chain Management

What is the goal of an efficient supply chain?

The primary goal of an efficient supply chain is to maximize profits while ensuring all resources are used optimally. This involves minimizing waste, reducing costs, and enhancing productivity.

Efficient supply chain management ensures that every step, from raw material procurement to product delivery, is streamlined. This results in cost savings and better resource utilization. For example, using just-in-time inventory methods helps in reducing storage costs.

What is an example of an efficient supply chain?

A prime example of an efficient supply chain is a company that can fulfill customer orders quickly and accurately despite handling a large volume of products daily. This efficiency is achieved through:

Fulfillment centers: Strategically located to minimize shipping times.

Advanced logistics: Utilizing sophisticated algorithms and robotics for faster sorting and packaging.

Real-time data tracking: Monitoring inventory and shipments to ensure prompt delivery.

This model demonstrates how combining technology, strategic planning, and logistics can create a highly efficient supply chain.

How can supply chain efficiency be improved?

Improving supply chain efficiency involves several strategies:

Training: Invest in training employees to manage different departments and stay updated with new operating procedures.

Automation: Implement automation for repetitive tasks to reduce human error and increase speed. This includes using advanced technologies like AI for demand forecasting and inventory management.

Software Implementation: Use CRM and WMS systems to integrate data analytics and streamline operations. Software like Method:CRM can automate data collection and reporting, making the supply chain more efficient.

By focusing on these areas, businesses can improve their supply chain efficiency, leading to cost savings and improved customer satisfaction.

Next, we'll explore how to measure supply chain efficiency.

Conclusion

Efficient supply chain management is crucial for maximizing profits and optimizing resources. By minimizing waste and reducing costs, businesses can streamline every step from raw material procurement to product delivery.

Continuous improvement is key. Regularly review and optimize your supply chain to maintain its efficiency. This involves training employees, automating processes, and implementing advanced software solutions.

At FulfilPackers, we offer technology-driven solutions designed to improve supply chain efficiency. Our services include warehousing, order fulfillment, and logistics custom to meet your unique needs. We focus on customer-centric services, ensuring high accuracy and on-time shipping rates.

By partnering with us, you gain access to scalable and innovative solutions that keep your supply chain running smoothly. Our expertise in e-commerce and 3PL fulfillment allows you to focus on growing your business while we handle the logistics.

Take the next step towards a more efficient supply chain with FulfilPackers. Contact us today to learn how our custom solutions can propel your business forward.

Efficiency in supply chain management is not a one-time fix but an ongoing process. Keep striving for improvement, and leverage technology and expertise to stay ahead in the competitive market. With FulfilPackers, you can achieve a highly efficient and responsive supply chain that meets your business goals.